Foundation Repair

Challenge

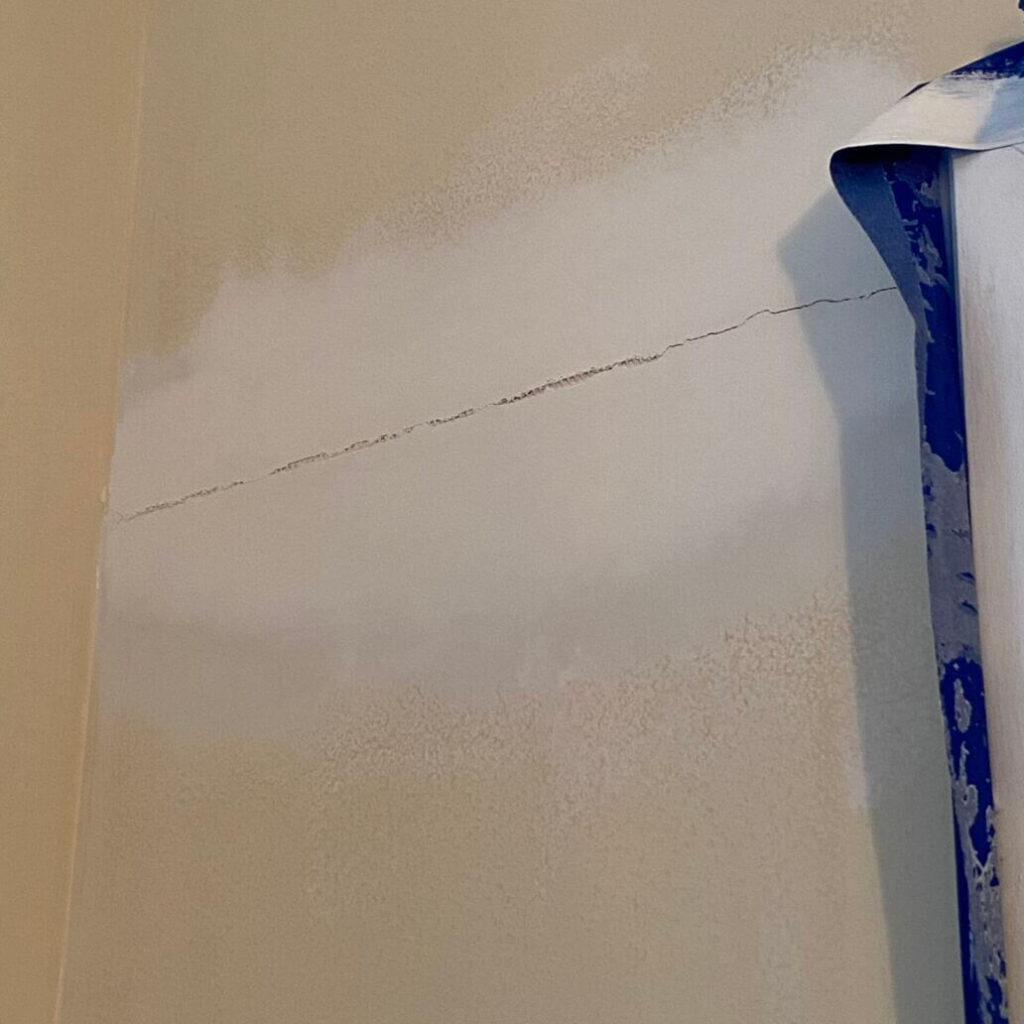

Chris and his wife had been noticing some issues with their home for about 5 years. A window or door sticking, some small cracks around door frames upstairs, and some cracking inside of their crawl space.

They wanted to paint a room in their home but were worried about a crack at the corner of their door frame, so they gave us a call. Our specialist, Bruce Cheatham, arrived and assessed the crack in the wall, as well as several windows and doors around the home that had been sticking, and severe cracking in their crawl space.

Chris and his wife wanted a solution that would stabilize their home and stop the cracking in the interior drywall, increasing the value of their home.

Solution

Upon assessment, our specialist recommended the use of our galvanized steel Push Piers from our partner, Supportworks, to stabilize their home and potentially lift it back to its original state.

The plan called for six Piers to be placed around the northeast corner of the home. Four of these piers would be located outside of the retaining wall of the home and the other two would be located inside the crawlspace on the other side of the wall. The piers were pushed into the ground until they hit bedrock, permanently stabilizing the foundation of the home.

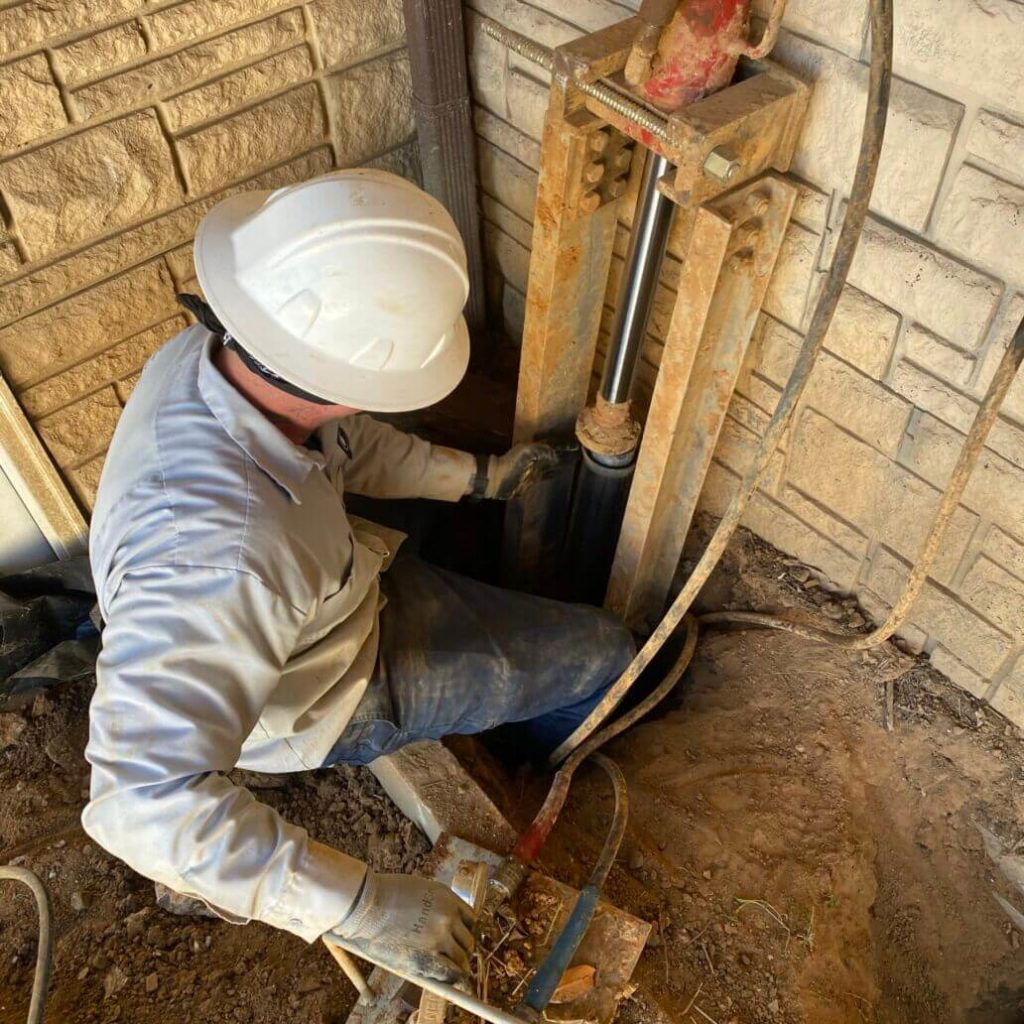

Our production crew arrived on the jobsite the day of installation and began by benchmarking the locations at which the piers were to be located. After the benchmarks were placed, they began excavating the holes where the piers would be placed.

Once the initial holes for the piers were excavated, the crew had to dig the rest of the way down to the footer. This was a crucial step as you must get underneath the footer to place the pier brackets in a spot where they can support and potentially lift the home.

After the footer was reached, it had to be prepped for the brackets to fit. This entailed using a jackhammer to grind the concrete footer down flat in the locations where brackets were to be placed. When the footer had been prepped, it was time to place the brackets and push piers. The brackets were fitted under the footer and the first piece of pipe was fed through them with a starter tube.

A hydraulic press was then positioned above the pier and used to drive pieces of pipe into the ground until the bedrock was reached. It took no more than one piece of 3 ½ ft. pipe to reach the bedrock. Each job is different and sometimes it can take up to 20-30’ of pipe to reach the bedrock. It is dependent on the soil makeup of your area.

After the piers were pushed, the crew had to cut off the excess pipe and cap them. Once cut and capped, a jack was used to potentially lift and stabilize the home. This part of the installation process was impressive as you could visibly see and hear the home being lifted. Once stabilized, it was time to backfill the holes with dirt and clean up the job site.

We were able to almost completely close the crack in the wall and stop all doors in the home from sticking. When asked about the results regarding the inside crack and the sticking of doors, Chris stated that “the difference was immediate.”

Project Summary

Specialist

Bruce Cheatham

Team Leader

James Allison

Materials Used

7 sections of push pipe (3.5’ each), 6 brackets, 6 starter tubes